The role of softener

- Supplement the natural oils lost by natural fibers in scouring, bleaching and other processes to make the hand feel better.

- Attaches to natural fibers or synthetic fibers to improve smoothness and strength, and improve hand feel.

Softeners are generally substances with the smoothness and feel of oils and fats. They adhere to the surface of the fibers to reduce the frictional resistance between the fibers and make the fibers lubricate and soft. There are also some softeners that can cross-link with some reactive groups on the fiber to achieve the purpose of washing durability.

Softener requirements

- Under various soft processing conditions, the working fluid should be very stable.

- Does not reduce the whiteness and color fastness of fibers or fabrics.

- The softened fiber or fabric is not easy to be discolored by heat, and there should be no changes in color, feel, or odor during storage.

- According to different processing requirements, it can have hydrophilic or hydrophobic properties, anti-static properties and other properties. It is resistant to washing or dry cleaning.

Types of softener

-

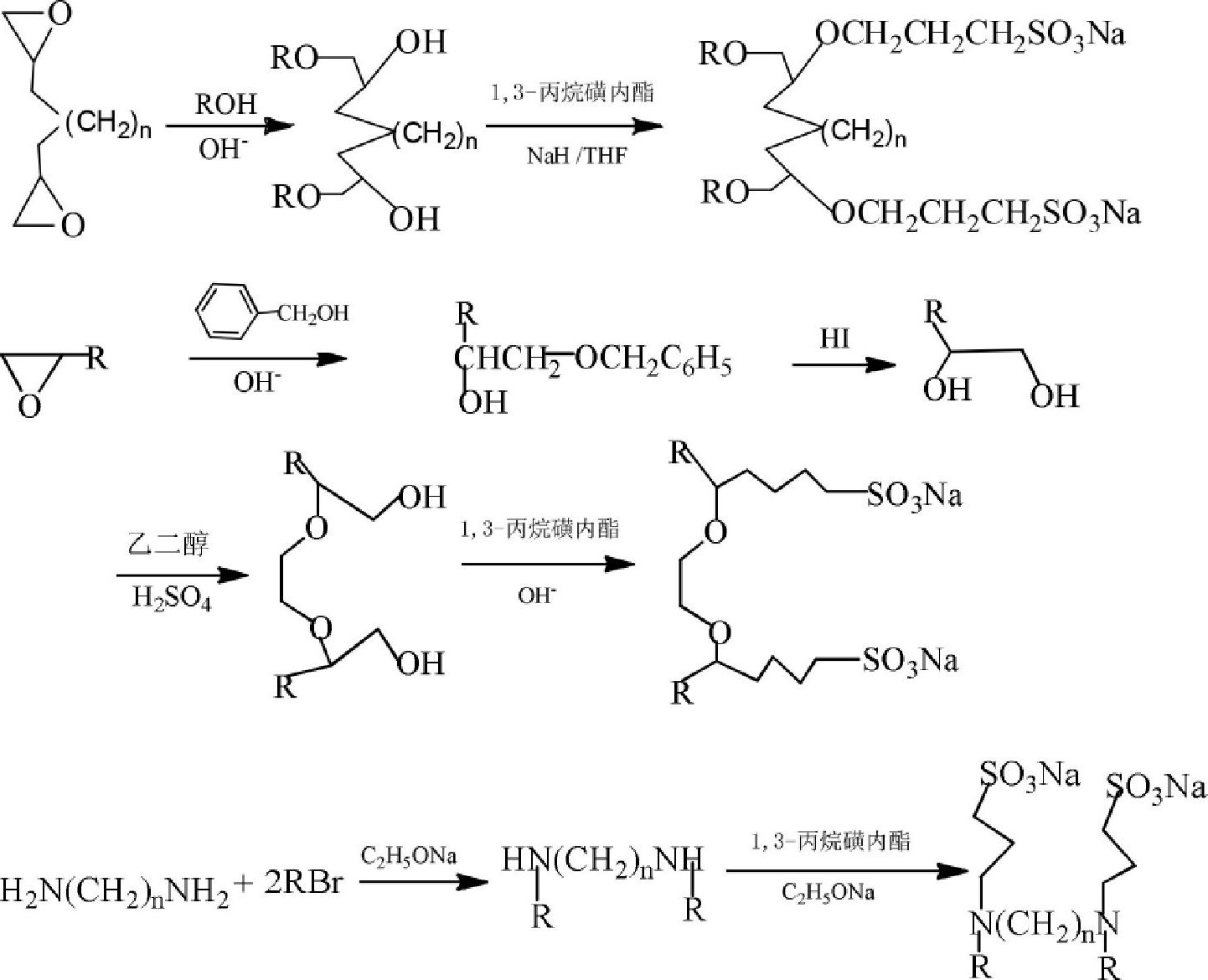

Anionic softener

In addition to soap, sulfonated oil, etc., the anionic softener is mainly composed of cationic compounds or anionic and nonionic compounds with long chain alkanes such as stearyl succinate sodium sulfonate and stearyl ester sulfate. Generally, it has good wettability and thermal stability, can be used in the same bath with optical brightener agent, and can be used as a softener for extra-white fabrics. It is also more suitable for cellulosic fibers, which can give fabrics better water absorption, but its adsorption to fibers is similar to that of direct dyes, which is relatively weak, so the softening effect is poor, and it is easy to be washed away. In addition, because it has a softening effect in the bath, it can be used for silk scouring to prevent scratches.

-

Non-ionic softener

Non-ionic softeners are generally polyoxyethylene esters (or ethers) of decaacid (or alcohol), fatty esters of pentaerythritol or sorbitol. Since non-ionic softeners have poorer absorption to fibers than ionic softeners, they can only play a smoothing effect. However, it can be used in combination with ionic softeners, has good compatibility with other materials, has good electrolyte stability, and does not have the disadvantage of yellowing the fabric. It can be used as a non-durable soft finishing agent, and can also be used as a synthetic fiber spinning oil. An important part of the agent.

-

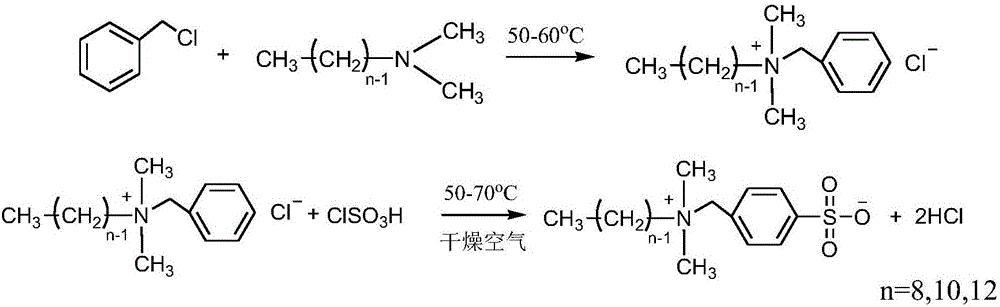

Cationic softener

Mainly because most fibers are negatively charged in water, cationic softeners are easily adsorbed on the surface of the fibers, have strong binding ability, can withstand high temperatures and washes, and the fabrics are plump and smooth after finishing, which can improve the wear resistance and wear resistance of the fabrics. It has a strong tearing force and has a certain antistatic effect on synthetic fibers. Therefore, it is widely used in cotton, nylon, acrylic and other fabrics, and this variety is also suitable for silk. However, some cationic softeners are prone to yellowing at high temperatures, accompanied by a decrease in light fastness. The cationic softener is generally a derivative of octadecylamine or dimethyloctadecylamine or a condensate of stearic acid and polyvinyl polyamine. According to its structure, it can be divided into tertiary amine softener, quaternary ammonium softener, imidazoline quaternary ammonium softener, dialkyl dimethyl quaternary ammonium softener and so on.

-

Amphoteric softener

Amphoteric softeners are a type of softener developed to improve cationic softeners. It has a strong affinity for synthetic fibers, and has no disadvantages such as yellowing and discoloration of dyes. It can also be used in the re-training process of silk to make the silk feel better. Amphoteric softeners can also be used together with cationic softeners to play a synergistic effect. Such softeners are generally of alkylamine lactone type structure.

This type of softener is an emulsion or microemulsion of polysiloxane and its derivatives, which can make the fabric have a good soft and smooth feel. The products include emulsion polymerization, polymer silicone oil emulsification, modification, compounding and other production techniques, which have basically formed a system and supply more varieties and brands. But the application effect and performance are still very different.